Analysis of the tile and ceramic industry / What are the problems of this industry? – Tejarat News

According to Tejarat News, one of the important and influential events in the 13th government should be considered the government’s decision to build 4 million residential units in four years. In fact, the annual construction of one million housing units is a matter of influence that can affect some construction and construction-related groups, groups such as cement, tiles and ceramics are among the industries that can be positively affected due to the construction of one million housing units per year. This happens.

The earliest forms of ceramic tiles date back to prehistoric times when the use of clay as a building material was developed in several early civilizations. Early modern tiles were roughly shaped and did not have the durability of today’s tiles. The materials of the tiles extracted from the bottom of the rivers were shaped into building blocks and dried in the sun.

The early tiles were raw, but even 6,000 years ago, people used them for decoration by painting and carving delicately on the tiles. It is the production of tiles and ceramics, the first works of this art in Iran date back to about 10,000 years BC, which were in the form of unbaked clay, and the first pottery kilns date back to about 6,000 years BC.

The ceramic industry is actually not limited to the manufacture of simple pottery vessels, tools and pieces of the past and has a great application in all dimensions of modern human civilization and technology today. The method of making and preparing all ceramic items is almost the same and depending on the application, there are slight differences in the production method.

Archaeologists have found that early humans were making ceramics around 24,000 BC. These ceramics were found in Czechoslovakia and are in the shape of animals and human figures, flat plates and balls. These ceramics were made from animal fat along with their bones, bone ash, and some fine-grained clay, and after shaping it, they baked it at a temperature of 500 to 800 degrees Celsius in dome-shaped or horseshoe-shaped furnaces.

But it is still not known why this type of ceramics was made. The first clay containers used were made in 9000 BC and were used to store food and edible seeds. The production of glass also started almost at the same time as pottery and in 8000 years ago in Egypt, so that due to the presence of calcium oxide along with sand and soda in pottery firing, it finally led to colored glazed pottery.

Tile and ceramic industry in Iran

Pottery is one of the most important and oldest artistic creations of mankind, which has remained stable since the beginning of pottery work. Due to the special geographical location and being on the highway of civilizations, the people of Iran have not only been among the first creators of pottery, but they have also been considered the most skilled creators. In Iran, pottery has been prevalent in four residential areas:

- Western region of Zagros mountains near Kermanshahan

- The southern shores of the Caspian Sea

- Northwest Azerbaijan

- Southeast of Iran

On the edge of the desert and in the central areas of Iran, pottery dating back 8,000 years can be seen. The oldest pottery objects found in Iran’s ancient excavations are the ones discovered in Ganj Dere Tepe in Kermanshah province, which dates back to the 8th millennium BC. Similarly, areas such as Ghari in the south of Mazandaran near Shahr (8th millennium BC) and in the second stage in the Zagheh area in Qazvin Plain, Cheshme Ali near Tehran and Silk Hill in Kashan.

In recent years, many wall and floor tile and ceramic factories have been established in Iran, and there has been a great transformation in this industry. China ranks first in the world’s tile and ceramic industry with the production of 5,700 million square meters; After China, Brazil, India, Spain, Iran, Indonesia and Italy are in the next positions respectively.

Iran can be called the fifth producer in the world. Unofficial statistics show that today about 150 tile and ceramic factories are operating and the annual production range is 300 to 400 million square meters. have given. Also, clay, which takes the first place in the production of tiles and ceramics and has a share of more than 78%, is of domestic origin, and we need 15 kilograms of soil per square meter of production.

Application of ceramic tiles

The applications of ceramic tiles are in floor construction, facade construction, production of sanitary ware, building materials such as decorative ceramics inside and outside the building, roof ceramics, anti-acid ceramics, etc.

Types of products of this industry include:

- Wall tile

- floor tile (ceramic)

- Porcelain tile (resistant ceramic)

- Granite tile

- Sanitary porcelain (Iranian and foreign toilet and toilet stones)

The structure of the ceramic tile industry

The word ceramic is derived from the Greek word kramos, which means baked clay or clay, and in fact, to introduce ceramics, it should be said that it is the art, science of making and using solid and fragile objects whose main and main material is soil. (These soils include: kaolin and clay)

Ceramic tile consists of two parts:

- The clay part that forms the main part and its skeleton, which is called the body.

- The second part is glaze, which is a glass material and is placed on the clay part.

Ceramic tile production per capita

The Ministry of Industry, Mines and Trade gave statistics: the per capita production of tiles and ceramics in Iran is 10,000 square meters, but in Italy and Spain it is 25,000 square meters per worker, which is significant.

In addition, Yazd province with 101 production units, Isfahan 21 and Razavi Khorasan 14 units have the highest population statistics of tile and ceramic production in the country.

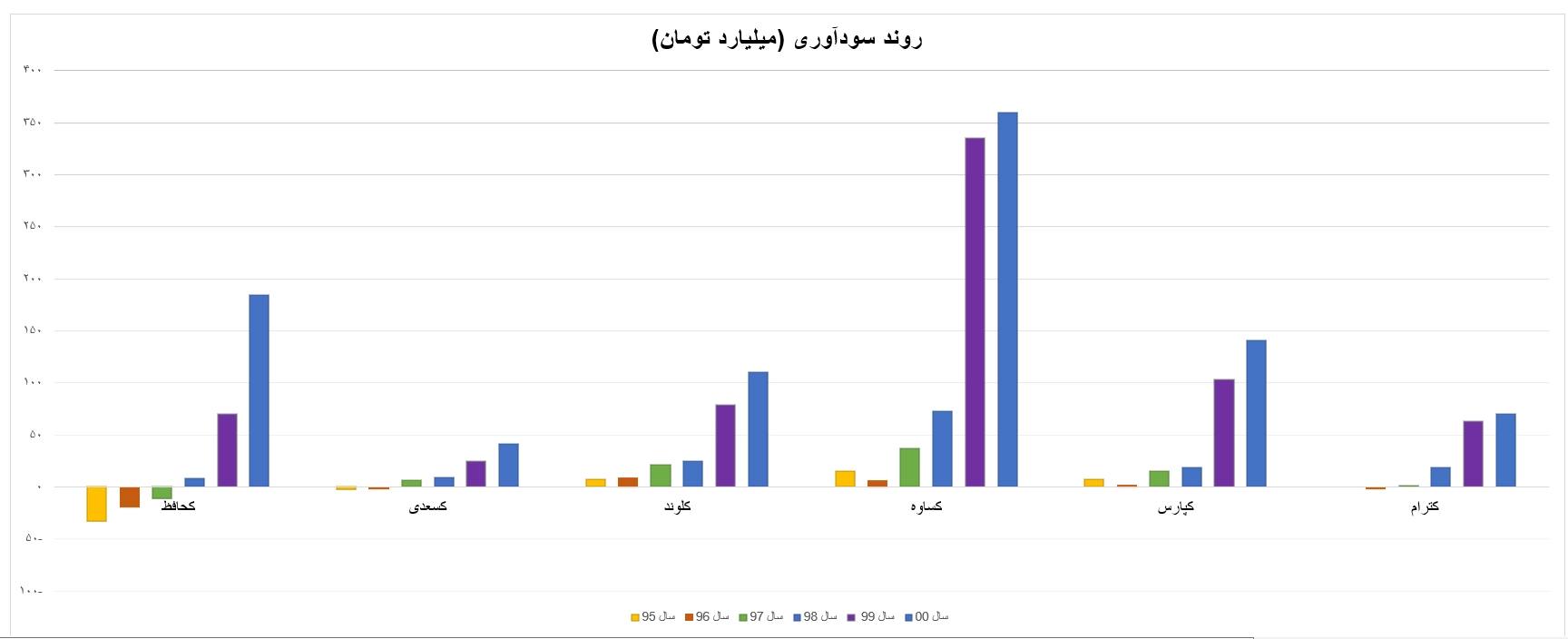

Production, export and consumption of the country in the last decade

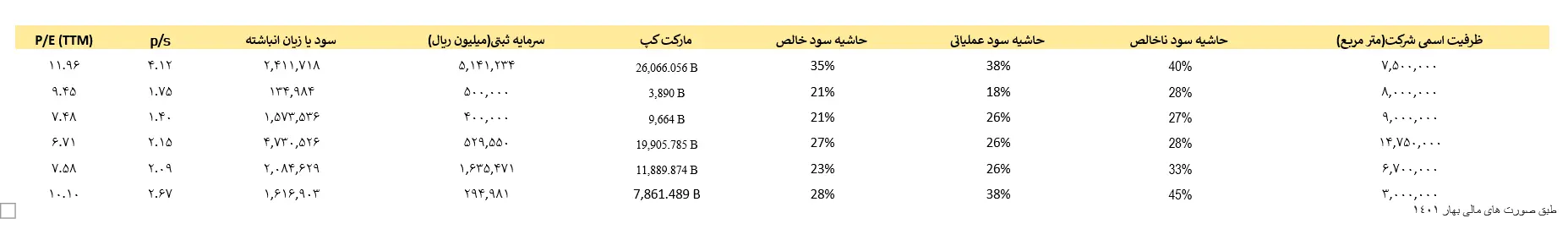

Selected tiles and ceramics in Bursa

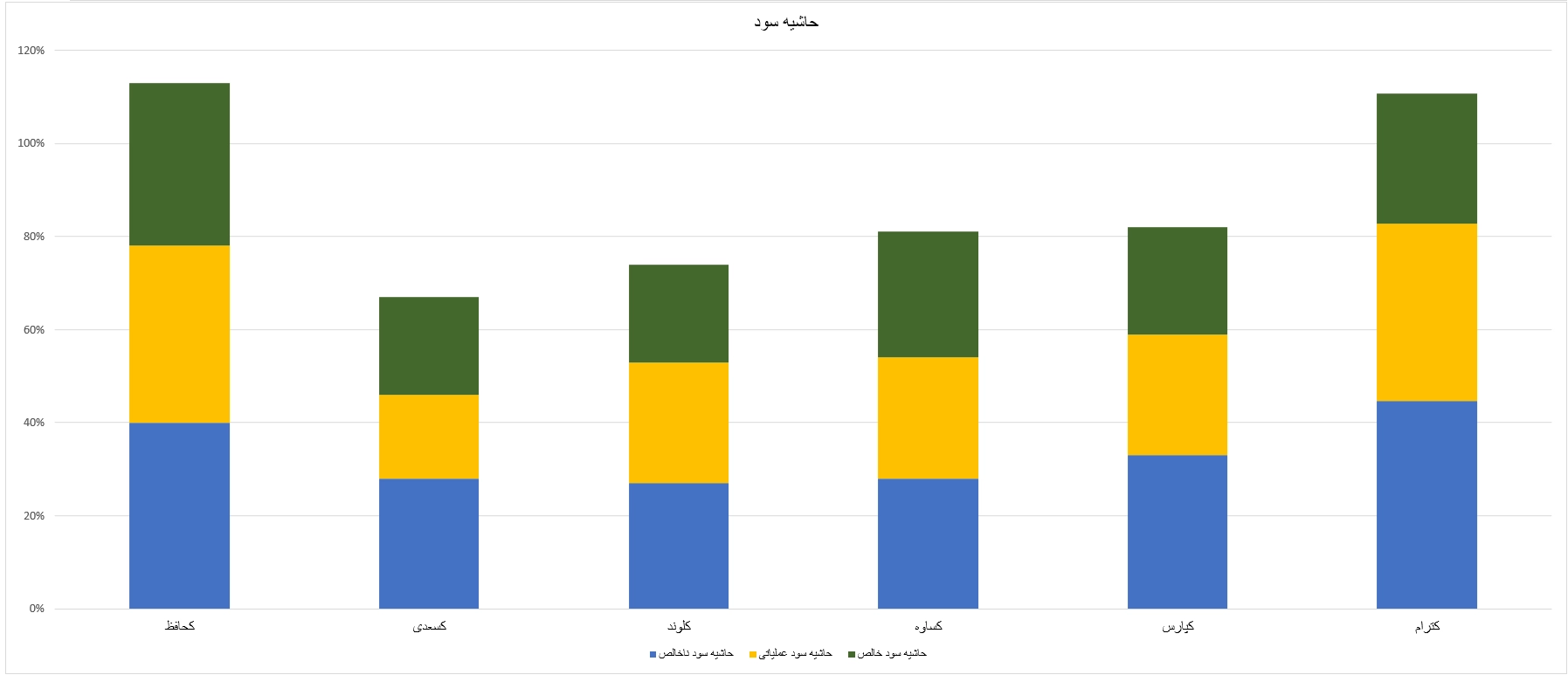

Industry analytical tips

- On average, between 45 and 50 percent of the cost of production is related to the cost of direct materials

- The large gap between production and nominal capacity in companies may decrease in the coming years

- The share of energy in the average production cost is 4 to 6 percent

- Most listed companies in the tile and ceramic industry are moving towards technological improvement and production efficiency

Weaknesses and threats of the tile industry in the country

- Continuation of construction stagnation in the country

- High competition of domestic producers

- The continuation of sanctions and problems related to the export of products and the import of up-to-date technology

- Exchange rate fluctuations and high import tariffs for imported raw materials

- High energy consumption and low productivity of production factors in a number of companies

- Lack of financial resources and working capital in the industry

- Increase in the price of energy carriers

- Poor export marketing

- Surplus of nominal capacity and the mismatch of domestic production growth with the trend of increasing exports

Strengths and opportunities of industry in the country

- Relatively cheap resources, raw materials and domestic energy

- export markets of neighboring countries

- The number of reliable suppliers of raw materials and equipment

- The possibility of starting the construction of 4 million houses

- The possibility of JCPOA agreement and the opening of new markets and the ease of importing equipment and machinery for companies

- Tile and ceramic substitute products are not competitive in terms of price

Technical status of the industry index