GNU water mills

GNU is the name of a place located 30 km north of Bandar Abbas, on the left side of the road from Bandar Abbas to Shiraz. The natural conditions of the place are such that the weather is milder and cooler than other areas of Hormozgan province.

This place has died and is now in focus due to its special circumstances. In the past, this attention has been paid to the use of available water for horticultural purposes, especially the cultivation of groves, as well as the construction of several mills to grind wheat.

At present, in addition to the past features, this place has been considered as a tourist area due to its proximity to Bandar Abbas, having a more suitable climate and also the natural landscape.

The most vital factor in the formation of such an environment (tourist place) is the Gnu spring, which originates from a small plain in the middle of the mountain and now hydrotherapy facilities have been established on its source and then its water flows to a relatively narrow valley to the west.

In this valley, the slope is relatively steep and the water flows out of the valley and the western plain of Gnu. The water used in the past has been used on its way to activate 6 mills and underground groves.

The name of the region

The name of the region and its naming to GNU is also due to the existence of this water. This word, abbreviated as “dirty” and “water”, means water that is rotten and has an unpleasant odor and is called GENO in the local dialect, similar to the other word GANO. Such springs in Persia are known as Ab Gando. Such springs have special properties due to their type of compounds that are considered today for the treatment of some diseases.

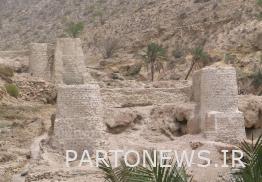

GNU mills

In an area of GNU, there are several old mills, all of which are located in the path of a spring called GNU. Gnu spring with a relatively high volume of water enters the valley with a relatively steep slope after a short distance in the middle mountain plain, which has made it possible to build mills in the best way. The existing slope does not require a long table to direct water into the ovens. By making a short table, water enters the oven and activates the mill.

Today, these mills are no longer used, the sound of water falling from the ovens can no longer be heard.

Operation system of GNU mills

GNU mills also have the characteristics of other Iranian mills in general, but in some details, due to the specific conditions of the region, there are differences that are mentioned.

When preparing the report on the mills, there were some ambiguities that were answered by asking questions from an experienced old man named Mohammad Zolfaghari who also owned one of the mills (the westernmost mill) and the necessary answers were obtained by matching the answers provided with the principles of mill operation. . The person in the situation where the mills were operating, observed them closely and even made and activated his own mill and was aware of the details of its construction and other mills.

One of the issues raised was the lack of any evidence of cover, either for the mill chamber or for the underwater canal and arch supporting the rocks. What was found was the difference between the type of chambers built in this place and the other chambers; In such a way that a short wall is made of stone and mortar and a mill chamber is created on it using wood and date branches. Instead of creating a cover using stone materials and mortar, olive wood was used to cover the table and the place where the turbine and mill stones were fixed, and wood was used in the parts of the canal that needed to be covered, which is the reason for the lack of arch works. On the body of the oven or other places. While the rectangular pit created at the bottom of the oven hole in the bottom of the table was the place of contract of the rectangular boards in the middle of which a pit stone was placed and the bottom rod of the turbine was placed on it.

The turbine wheel is made of wood called Kahoor. The upper rod passed through the center of the lower wheel and was fastened to the upper rock with a clamp, and was fastened with wood to prevent the wheat grains from falling into the channel around the rod. To pour wheat on the stone, dowels were used and to adjust the amount of wheat shedding, four ropes were used on all four sides of the dowels, which was done by pulling them up and down, and the resulting flour was different in terms of softness and roughness. A mortar-shaped stone was placed at the exit of the water from the oven so that the body of the exit would not be eroded.

Current status of GNU mills

There are six mills in the valley that are built along each other. The condition of these mills varies in terms of safety.

Mill No. 1:

The lowest mill is located at the beginning of the western grove at an altitude of 205 meters above sea level. The oven condition of this mill is better than other ovens and the owner’s name is a person named Mohammad Zolfaghari, who according to him said that this mill has been used for the past decade and now it can be easily restored. This mill has a coated layer on the outside and a coated layer on the inside, and there is no evidence of encroachment on it. Below this mill is a garden.

Mills No. 2 and 3:

Along Mill No. 1 and at a higher level, two more mills are built adjacent to each other, with the water conduction table of the two ovens adjoining each other. This action, due to the creation of a larger width, has made the tables more robust and has also been done sparingly in bodybuilding. The furnaces of these two mills are very far from each other.

Mill No. 2: It is located at an altitude of 209 meters above sea level. The table and oven of this mill are at a lower level than mill number 3. The water conduction table separates from the other mill channel at an angle of approximately 90 ° and reaches the mill furnace at a 90 angle. The difference between the table and the oven surface of these two mills is about 90 cm. The oven depth of this mill is 4.5 meters. The upper part of the mill is double-layered. The water outlet channel in front of the oven directs the water directly outwards. In front of the outlet of this oven, a rectangular hollow space has been created.

Mill No. 3: It has a special position compared to other mills. This mill, which is built near the Abbaro Bridge and a small valley, has a more beautiful natural view. This mill is located at an altitude of 211 meters above sea level. The noteworthy point about this mill is the presence of multiple coated layers on the outer body of the furnace.

The main layer is coated on the stone with a thickness of 2.2 cm, the second layer is coated with an average thickness of 2.5 cm on the first layer, the third layer is coated with a thickness of 2 cm on the second layer, the fourth layer is coated with a thickness of 1.3 cm on the third layer The fifth layer is 1.2 cm thick on the fourth layer. Inside the oven there is a coated layer that is very eroded.

In front of the mill, there is a rectangular depression and the water is directed through a channel to the table on the water bridge; In front of the mill oven, light remnants of a chamber can be seen. By cleaning it, a room measuring 2.60 m (the front side of the oven), two parallel sides of the table are 3.35 m and the other side is 26.2 m, with the water table in the middle. It has passed.

Mills No. 4 and 5:

Above mills No. 2 and 3, another pair of mills has been built side by side, and the construction of these mills together, like the previous two mills, is of interest in some respects. The water conduction table of the two ovens is made like mills 2 and 3 attached to each other; But the furnaces of the two mills are a short distance from each other. The furnaces of the mills differ in height from each other. Stone and mortar have been used in the construction of tables and ovens, and the dimensions of ovens are different in terms of opening and height.

Changes in coatings and the use of cement coatings indicate the continued use of mills, even in the not-so-distant past.

Mill No. 6:

The first and highest mill built on the route is only a small remnant of it and is located at an altitude of 220 meters above sea level. The table is completely destroyed and only a small part of the end of the oven is left. There are no signs of installation under the oven.

The collection of GNU water mills belonging to the Qajar period in 1380, number 3974, has been registered in the list of national monuments.

* Report: Mehdi Parand